How to Choose the Right High Voltage PCB Design

As electronics continue to push the boundaries of innovation, one area seeing remarkable advancement is High Voltage PCB design. From robotics to telecommunications, industries are demanding more complex, reliable, and high-performance circuit board solutions. This article explores how to choose the right high voltage PCB, what makes these boards essential in modern applications, and why expert manufacturing is critical.

Understanding High Voltage PCB Design

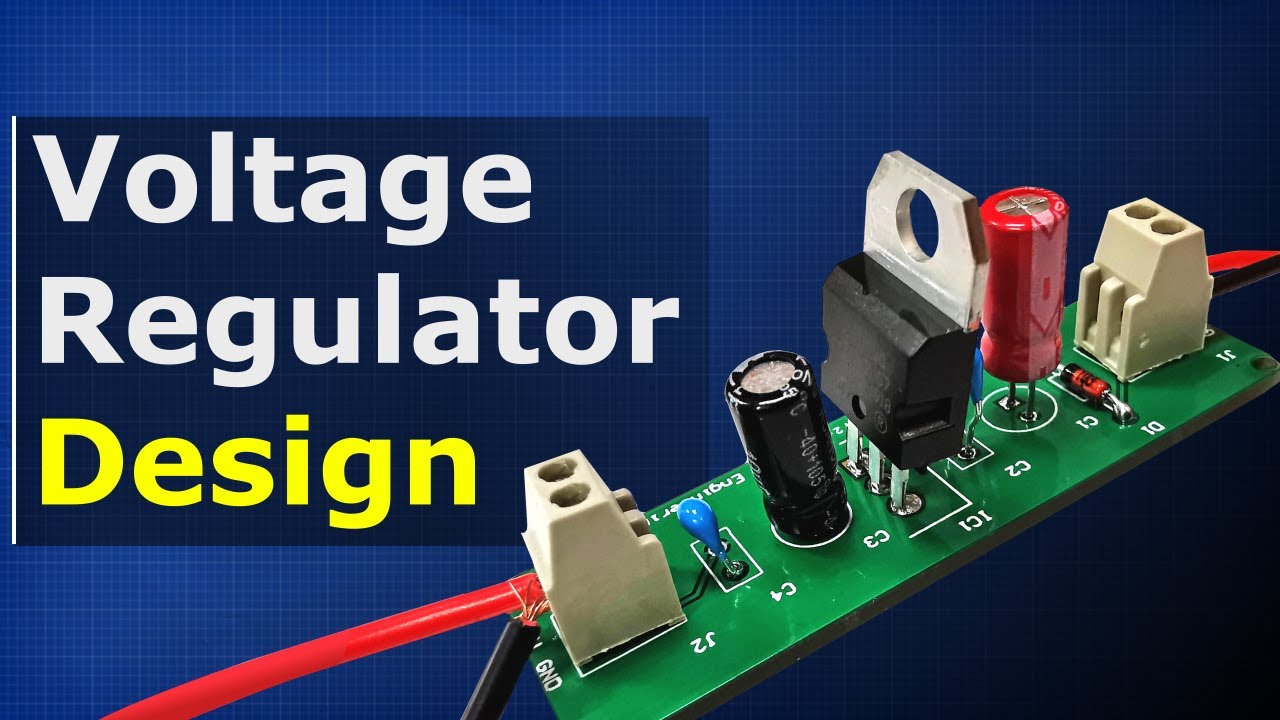

High voltage PCBs are specialized circuit boards built to handle higher voltages than standard PCBs. These are crucial in industries where electrical insulation, safety, and performance are non-negotiable. Typically, any PCB that handles over 100V can be considered high voltage, though the threshold may vary depending on the industry.

Key Features of High Voltage PCBs:

Wider spacing between conductive paths

Thicker copper layers for current handling

Special dielectric materials to prevent arc-over

Robust insulation and protective coatings

Understanding these design elements helps engineers ensure that the final product performs reliably under high voltage conditions.

Why High Voltage PCBs Matter

High voltage PCBs are at the heart of applications like

Power conversion systems

Industrial automation equipment

Telecommunication infrastructures

Electric vehicles and charging stations

Medical imaging device

Their role in maintaining safe, efficient power distribution cannot be overstated.

Material Selection for High Voltage Applications

Material selection plays a vital role in the durability and safety of a high voltage PCB. Some common materials include:

FR-4: Suitable for lower-end high voltage applications.

Polyimide: Offers better thermal and mechanical stability.

Ceramic substrates: For ultra-high voltage and high-frequency performance.

Advanced dielectric materials help reduce the risk of dielectric breakdown and ensure long-term reliability.

Design Considerations for High Voltage PCBs

To achieve optimal performance, engineers must consider several factors:

1. Creepage and Clearance

These terms refer to the minimum distance between conductive elements:

Creepage: Distance along the board’s surface

Clearance: Direct line (air gap) between conductors

Proper spacing prevents unintended arcing and ensures safety under high voltage conditions.

2. Board Thickness and Copper Weight

Heavier copper (2 oz/ft^2 or more) and thicker boards offer better heat dissipation and current handling.

3. Coatings and Insulation

Protective coatings like conformal coating and potting compounds add layers of insulation, shielding circuits from moisture and contaminants.

4. Thermal Management

Since high voltage boards can generate significant heat, thermal vias, heatsinks, and thermally conductive materials are often used.

Applications in Robotics and Telecommunications

Robotics

Modern robotics systems require high-voltage circuits for motor control, sensor integration, and power distribution. These PCBs must be lightweight yet robust enough to handle dynamic loads and electromagnetic interference.

Telecommunications

In telecommunications, high voltage PCBs are used in signal transmission systems, base stations, and fiber optic network interfaces. These applications require minimal signal loss and high-speed performance.

In both industries, the trend is moving toward Rigid-Flex PCBs and High-Frequency PCBs for enhanced performance and space-saving capabilities.

Benefits of Advanced PCB Technologies

Rigid-Flex PCBs

Rigid-Flex designs combine rigid and flexible substrates into one board, allowing for:

Greater design freedom

Space efficiency

Enhanced durability in dynamic environment

High-Frequency PCBs

High-frequency designs operate efficiently at GHz levels, ideal for high-speed data and signal transmission in telecommunications and radar systems.

Why Manufacturer Expertise Matters

Working with an experienced PCB manufacturer is essential. From design verification to final testing, each step must comply with international safety and quality standards.

An expert manufacturer like globalwellpcba.com offers:

Custom high voltage PCB design

Precision engineering

Quality assurance with ISO certifications

Advanced material sourcing

On-time delivery and responsive customer support

Choosing a professional ensures your project meets both performance requirements and compliance standards.

Final Thoughts

High voltage PCBs are vital in powering the technologies of tomorrow. From industrial robotics to cutting-edge telecommunications, selecting the right design and manufacturer can be the difference between success and failure.

Whether you’re designing for harsh environments or high-speed data transfer, don’t compromise on quality. Leverage the expertise of proven professionals in High voltage PCB design to ensure safe, efficient, and long-lasting electronic solutions.