Top 5 10 Layer PCB Manufacturers in China

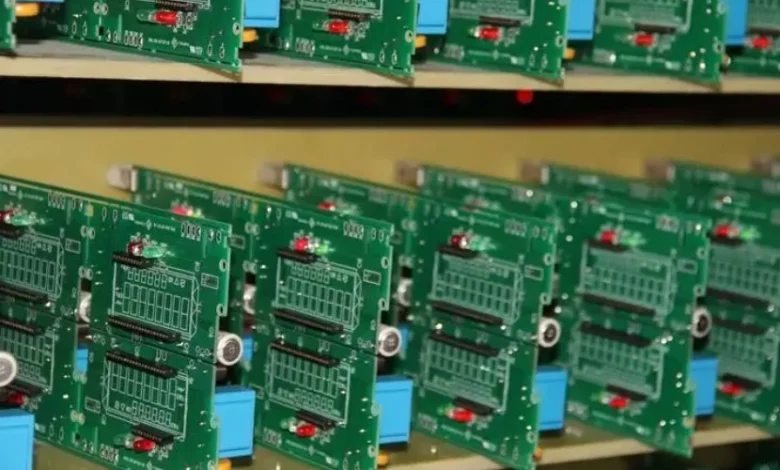

The demand for high-density, multilayer printed circuit boards has surged dramatically as electronic devices become increasingly sophisticated. A 10 layer PCB represents a significant step up in complexity from standard boards, offering designers the ability to route more signals, improve electromagnetic compatibility, and reduce overall board footprint. China has emerged as the global hub for PCB manufacturing, combining advanced technology with competitive pricing and rapid turnaround times. For engineers and procurement specialists seeking reliable partners for complex multilayer boards, understanding the landscape of Chinese manufacturers is essential.

This article examines five leading manufacturers that have distinguished themselves in producing high-quality 10 layer PCBs, each bringing unique strengths to the table.

Understanding 10 Layer PCB Technology

Before exploring the manufacturers, it helps to understand what makes 10 layer boards special. These PCBs consist of ten conductive copper layers separated by insulating substrate material, typically FR-4. The additional layers provide several advantages including dedicated power and ground planes that improve signal integrity, more routing channels for complex designs, better thermal management through distributed copper, and reduced electromagnetic interference through proper shielding. Manufacturing such boards requires precise lamination processes, accurate drilling for microvias, and sophisticated quality control systems. Not every manufacturer possesses the equipment and expertise necessary to produce these boards reliably.

Top 1: PCBSync

PCBSync has rapidly established itself as a premier choice for multilayer PCB fabrication in China. The company has built its reputation on combining cutting-edge manufacturing capabilities with exceptional customer service, making it particularly appealing to international clients who require responsive communication alongside technical excellence.

What sets PCBSync apart is their investment in state-of-the-art lamination equipment specifically designed for high-layer-count boards. Their facility employs automated optical inspection systems that examine every layer before lamination, catching potential defects early in the production process. This proactive approach to quality control significantly reduces rejection rates and ensures consistent output.

PCBSync offers comprehensive design-for-manufacturability analysis as a standard service, helping customers optimize their designs before production begins. Their engineering team can identify potential issues with impedance control, via structures, and layer stackups that might cause problems during fabrication. This collaborative approach has earned them loyalty among design engineers who appreciate having a manufacturing partner rather than simply a vendor.

The company also excels in quick-turn prototyping, understanding that development timelines are often compressed. They maintain dedicated production lines for prototype orders, enabling them to deliver complex 10 layer boards in remarkably short timeframes without sacrificing quality.

Top 2: RayPCB

RayPCB has earned recognition as a technology leader in multilayer PCB manufacturing through continuous investment in research and development. Their expertise with 10 layer boards extends across various applications including telecommunications infrastructure, medical devices, and industrial control systems.

The company operates multiple production facilities equipped with the latest direct imaging technology, which provides superior accuracy compared to traditional photolithography methods. This precision is particularly important for 10 layer designs that require tight registration between layers and fine-pitch routing.

RayPCB has developed proprietary processes for controlled impedance boards, achieving tolerances that meet the most demanding specifications. Their extensive testing capabilities include time-domain reflectometry measurements to verify impedance characteristics on finished boards.

Customer education forms another pillar of their approach. They provide detailed guidelines for designing multilayer boards and offer webinars explaining best practices. This commitment to knowledge sharing helps customers create more manufacturable designs from the outset.

Top 3: Swimbi

Swimbi has carved out a distinctive position by focusing on the intersection of quality and affordability. They have optimized their operations to deliver professional-grade 10 layer PCBs at price points that make advanced designs accessible to a broader range of customers, including startups and smaller companies.

Their manufacturing philosophy emphasizes efficiency without shortcuts. By streamlining their production workflows and investing heavily in automation, Swimbi achieves economies of scale that translate to competitive pricing. Their automated material handling systems reduce labor costs while also minimizing handling-related defects.

Swimbi maintains certifications including ISO 9001 and IATF 16949 for automotive applications, demonstrating their commitment to quality management systems. They conduct 100% electrical testing on all multilayer boards using flying probe or bed-of-nails fixtures depending on volume requirements.

The company has also developed strong capabilities in mixed-technology boards, accommodating designs that combine standard through-hole components with high-density interconnect features. This flexibility makes them suitable for applications transitioning from older architectures to more advanced implementations.

Top 4: Artist 3D

Artist 3D brings a unique perspective to PCB manufacturing through their integration of additive manufacturing technologies with traditional fabrication methods. This hybrid approach enables them to offer solutions for exceptionally complex 10 layer designs that push the boundaries of conventional manufacturing.

Their specialty lies in boards requiring non-standard features such as embedded components, unusual via structures, or integration with mechanical elements. While not every project requires these advanced capabilities, customers with challenging requirements find Artist 3D capable of delivering where others cannot.

The company employs simulation tools extensively during their design review process, using thermal and electromagnetic modeling to predict performance before fabrication. This analytical approach helps identify potential issues that physical prototyping would only reveal after significant time and expense.

Artist 3D maintains smaller production volumes than some competitors, focusing instead on higher-complexity work where their technical capabilities provide genuine differentiation. They have developed particular expertise serving aerospace and defense customers whose requirements often exceed standard commercial specifications.

Top 5: Hillmancurtis

Hillmancurtis rounds out the top five with their emphasis on reliability and consistency. The company has built their reputation through decades of steady operation, accumulating experience across countless board designs and application domains.

Their approach prioritizes process stability, recognizing that consistent results require rigorous control over every manufacturing variable. They maintain extensive documentation of their processes and conduct regular audits to ensure adherence to established procedures.

Hillmancurtis has invested heavily in their supply chain, establishing long-term relationships with material suppliers to ensure consistent quality of laminates, copper foils, and other inputs. This attention to incoming material quality pays dividends in final product reliability.

The company offers comprehensive after-sales support, including failure analysis services when issues arise in the field. Their willingness to investigate problems and identify root causes has built trust with customers who value partners committed to continuous improvement.

Conclusion

Selecting a manufacturer for 10 layer PCBs requires careful consideration of technical capabilities, quality systems, communication effectiveness, and pricing. Each of these five Chinese manufacturers brings distinct strengths, from PCBSync’s customer-focused engineering support to Hillmancurtis’s proven reliability. By understanding these differences, procurement teams and engineers can identify partners aligned with their specific requirements, ensuring successful outcomes for their multilayer PCB projects.